Revolutionizing Mining Operations with IIoT

At Arrow Automation, we are at the forefront of integrating cutting-edge technology into industrial operations. Our latest project involved deploying an Industrial Internet of Things (IIoT) solution at a remote mine site, significantly enhancing operational efficiency and data management.

Project Overview

Objective: The goal was to implement a robust IIoT system that could reliably monitor and control various mining operations remotely. This system needed to provide real-time data access, historical logging, and secure user interaction.

Technology Used:

- DNP3 Protocol: We utilized the Distributed Network Protocol (DNP3) for its reliability and efficiency in remote monitoring and control applications. This protocol ensured seamless communication between the remote units and the central server.

- Cloud Server with Historical Logging: The remote units communicated with a cloud server capable of logging historical data. This setup allowed for comprehensive data analysis and long-term storage, providing valuable insights into the mine’s operations.

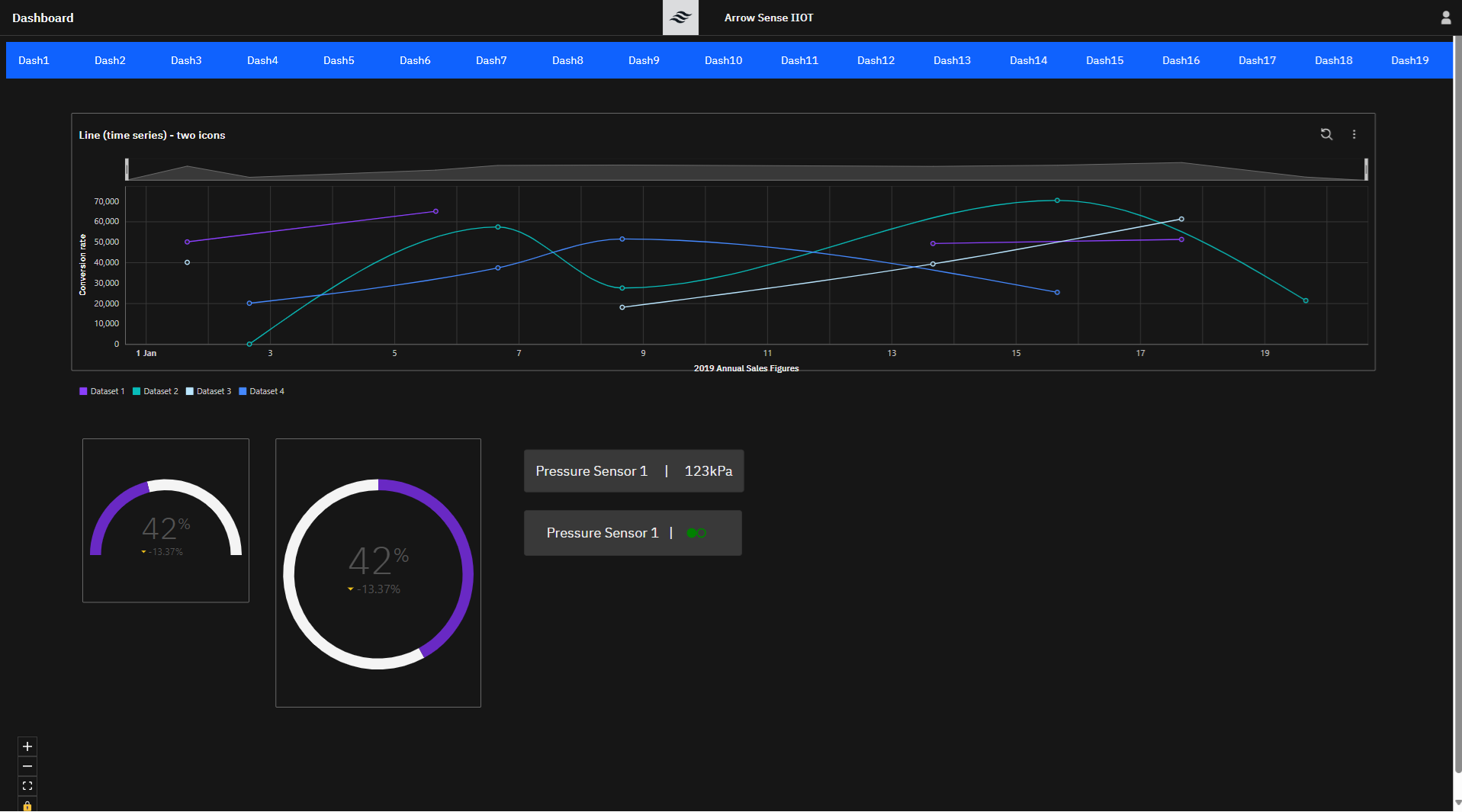

- Web Interface with MFA Authentication: To ensure secure access, we developed a web interface that required multi-factor authentication (MFA). This interface allowed users to control the system and access historical data from anywhere, ensuring both convenience and security.

Implementation and Challenges

Remote Monitoring: The remote units were strategically placed throughout the mine site to monitor various parameters such as equipment status, environmental conditions, and operational metrics. Using the DNP3 protocol, these units transmitted data to the cloud server in real-time.

Data Management: The cloud server’s historical logging capability was crucial for this project. It enabled the storage of vast amounts of data, which could be analyzed to identify trends, predict maintenance needs, and optimize operations.

User Interface: The web interface was designed with user-friendliness and security in mind. Multi-factor authentication ensured that only authorized personnel could access the system, while the intuitive design made it easy to navigate and utilize the data effectively.

Challenges:

- Remote Location: The mine’s remote location posed significant challenges in terms of connectivity and power supply. We addressed these by using reliable communication technologies and ensuring robust power solutions for the remote units.

- Data Security: Ensuring the security of sensitive operational data was paramount. Implementing MFA and using secure communication protocols helped mitigate potential security risks.

Successful Outcome

The IIoT system we implemented has transformed the mine’s operations. With real-time monitoring, comprehensive data logging, and secure remote access, the mine can now operate more efficiently and make data-driven decisions. The ability to control and analyze historical data through a secure web interface has empowered the mine’s management team, leading to improved productivity and reduced downtime.

At [Your Company Name], we are committed to delivering innovative solutions that drive operational excellence. This project is a testament to our expertise in IIoT and our dedication to meeting the unique needs of our clients.

Contacts us to learn what we can do for you. Contact us!